diy press brake control

Max Bending Radius deg 110 Max Bending Cap. Im building a diy press brake for bending sheet metal.

Building A 40 Ton Hydraulic Press Brake Machine 21 Steps With Pictures Instructables

Use the standard 2 die opening min.

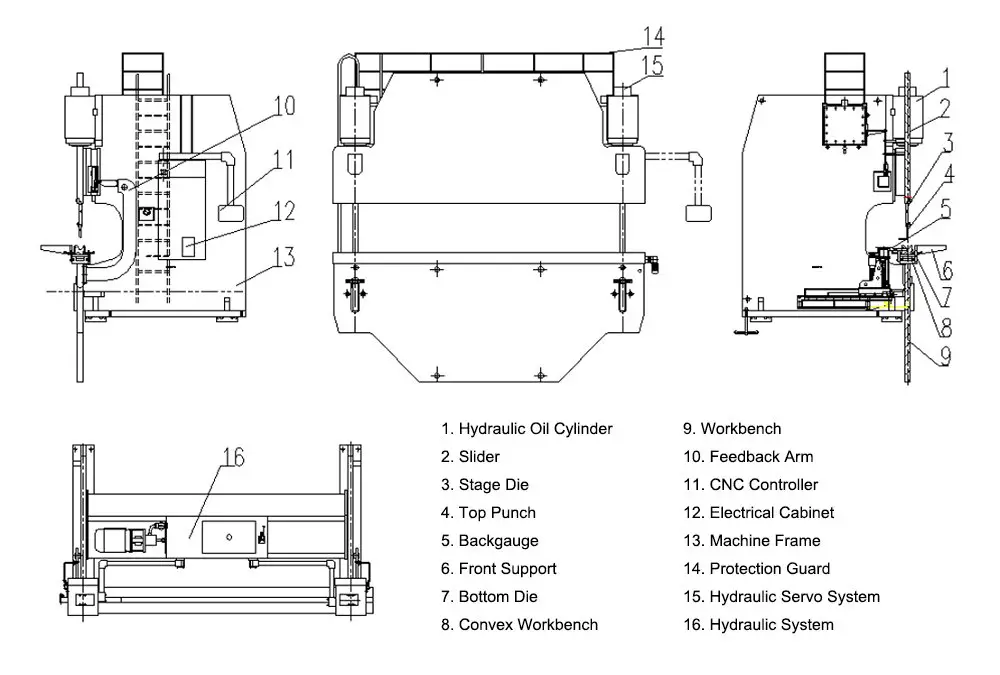

. Extensible modular high-end press brake control solutions. CNHs Fargo plant also upgraded its backgauge with a powered R-axis which recognizes tooling and eliminates the need to raise the backgauge manually during die changes. Excellent for the long run and small piece part production shop where uniform piece part forming is required.

20 TON Press Brake DIY Builder Kit Press Brake kit comes unassembled you do the final assembly and weldingDesigned to fit the Harbor Freight 20 ton hydraulic press Item 32879 60603Press brake kit includes an adjustable back stop for accurate and repeatable bends. In manufacturing AI is rising. Press the red motor stop button.

My question is whether Arduino in the opinion of the forum is a good platform for designing a control unit for the brake press. How To Build a Press Brake. Daniel from The Metal School shows you how to build a press.

DA-40 series The DA-40s and DA-40Touch series press brake controls. As you load and unload your tooling make sure it is seating correctly. - And then simple fill in the blanks for bend 1 angle length finger ht offset crown.

Every press brake machine has dies and bends that can be changed out in order. Remove power from the main distribution panel to which the press brake is connected. Turn the main switch on the electric cabinet door to position 0 and lock it with a padlock.

So on for each additional bend to build a simple program to bend up. DA-50 series The DA-50Touch series press brake controls. Drill press with a Blu-Mol bi-metal 20mm hole saw recommended cutting speed is 440 rpm.

Compact solutions without compromise. Mechanical press brakes use a spring-loaded trigger. The modern press brake is a remarkable machine by any standard.

Things I want it to do. Turn off any auxiliary devices by turning the selector switch to position 0. Mechanical Press Brake Control with Automatic Slow Forming.

May 6 2018 Roadkill Customs DIY Projects How To DIY. A press brake is a great tool to have in your shop so that you can bend plate steel. Sophisticated conventional press brake control solutions.

It touts ram and backgauge-location repeatability measured in microns. Retains Mechanical Pedal to Slow Form Parts and to Retain Operator Feel for Forming. Your 4 press brake would require 80 tons if you want to run 14 plate and.

Key of getting this to work is having a reliable way of measuring the bend angle. A 115 mm angle grinder cutoff and grinding disks. IIRC without looking at the chart 14 plate will require with a standard.

Whenever you start running into problems with your press brake one of. Looking for options on a cnc control retrofit for a press brake on a budget. The machines controller calculates exact values based on pure mathematical modeling predicting the backgauge location and the rams depth of penetration into the die space.

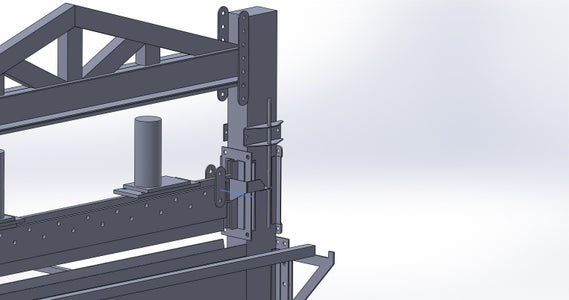

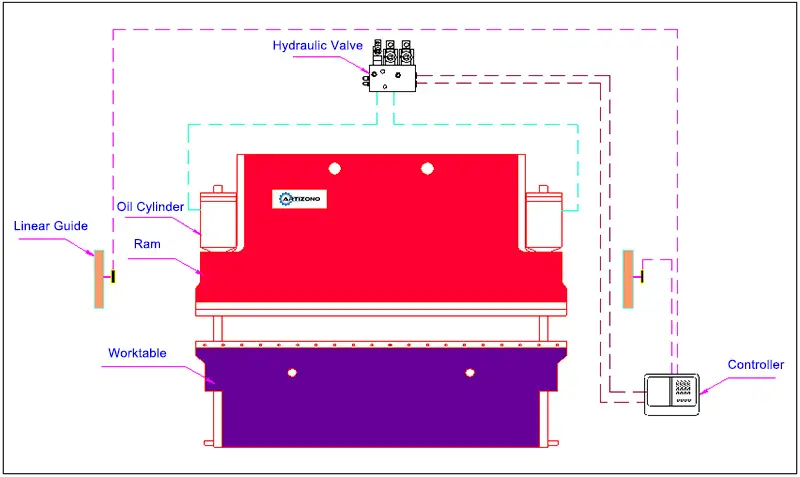

Pneumatic brakes use an air trigger. Control synchronization a height hydraulic cylinders on a press brake. The physical design of the press is quite straight forward.

You also need to periodically check and verify that your tooling is aligned correctly. Di-Acro 16-24 Manual Press Brake 8 ton w factory stand metal fabrication LQQK. Total noob here looking for guidence and advice.

The upper tool should be seated under a little bit of tonnage to make sure its up where its supposed to be. Excellent for the long run and where versatility is needed during. - Simple fill in the blank boxes or selections for punch die material thickness.

8x thickness die opening 20 tons per lineal foot. A hydraulic brake can be halted any time during its stroke giving operators greater control over the process. Automec Inc Waltham Mass manufactures CNC gauging systems and designs positioning systems with programmable controls that can be retrofitted to press brakes shears cut-off saws and punches.

When the triggers are pressed on these brakes the machine begins a cycle. 4 metres taper flange 100mmx50mm steel channel the taper flange is cheaper and stronger than the parallel flange 2x 1metre side uprights.

Single Spindle Electric Press Brake Press Brake Metal Bending Tools Metal Working Tools

Press Brake 101 Everything You Need To Know 2022 Updated Machinemfg

Building A 40 Ton Hydraulic Press Brake Machine 21 Steps With Pictures Instructables

Easy Diy Guide To Press Brakes Tooling Metal Folding Magnabend Cnccookbook Be A Better Cnc Er

12 Hydraulic Press Brake 20 Ton Metal Steel Bending Machine V Die Diy Kits V Block Attachment 20 Ton Hydraulic Press Engine Aliexpress

Easy Diy Guide To Press Brakes Tooling Metal Folding Magnabend Cnccookbook Be A Better Cnc Er

Diy Cnc Press Brake In Action Youtube

Swag 20 Ton Press Brake Heavy Duty Diy Builder Kit Swag Off Road

Easy Diy Guide To Press Brakes Tooling Metal Folding Magnabend Cnccookbook Be A Better Cnc Er

My Press Brake Diy The Garage Journal

Diy Press Brake 13 Steps With Pictures Instructables

Yububottles On Twitter Press Brake Metal Bending Tools Diy

Diy Press Brake 13 Steps With Pictures Instructables

300t3200 Cnc Press Brake With Da58t Controller Press Brake Cnc Press Brake Press Brake Tooling

Press Brake 101 Everything You Need To Know 2022 Updated Machinemfg

Building A 40 Ton Hydraulic Press Brake Machine 21 Steps With Pictures Instructables

Swag Offroad 50 Finger Press Brake Build Plasmaspider Com

Building A 40 Ton Hydraulic Press Brake Machine 21 Steps With Pictures Instructables